Abrasive Media

Tochu Thailand Co., Ltd. is able to supply our customers with a wide range of abrasive media, ensuring that their production demands can be achieved at all times. Below is a brief overview of our standard product range. Please note that other media types and customized sizes of the various abrasives are available on request.

Your One Stop Supplier

Copyright © John Smith, All Rights Reserved.

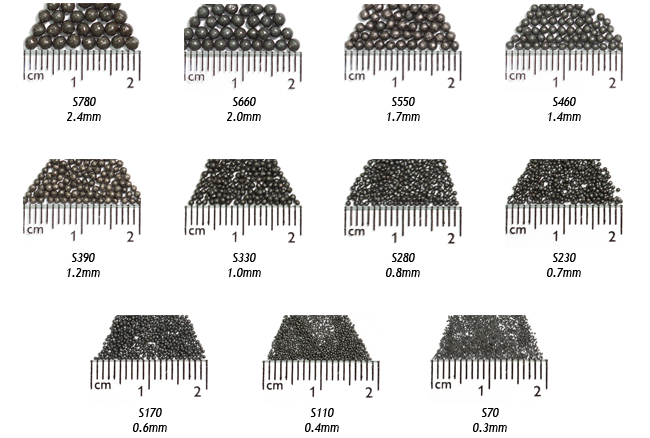

Steel Shot

Copyright © John Smith, All Rights Reserved.

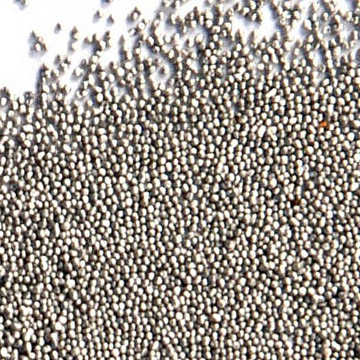

Steel Shot is manufactured by the atomization of molten steel followed by a series or thermal and mechanical treatments, to achieve the products final characteristics. The resulting spherical heat-treated special steel particles are uniform martensite and range from 0.3 to 2.8 mm diameter in size.

This media is mainly used in applications in which a great impact force and “hammering action” is required to clean and in some cases also to peen a variety of steel and foundry products.

The typical hardness of this media ranges between 40 – 61 HRC.

This media is mainly used in applications in which a great impact force and “hammering action” is required to clean and in some cases also to peen a variety of steel and foundry products.

The typical hardness of this media ranges between 40 – 61 HRC.

Copyright © John Smith, All Rights Reserved.

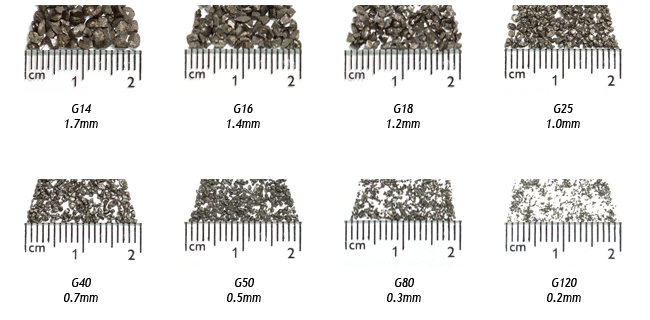

Steel Grit

Copyright © John Smith, All Rights Reserved.

Steel Grit is also manufactured by the atomization of molten steel followed by a series or thermal and mechanical treatments, of which one treatment is the crushing of the round particles to achieve the products final characteristics. The resulting angular and sharp edged particles are much more aggressive and are able to generate a higher surface profile, therefore making this abrasive a good choice for the surface treatment prior to paint coating. The typical hardness of this media ranges between 40 – 61 HRC.

Copyright © John Smith, All Rights Reserved.

Stainless Steel Shot

Copyright © John Smith, All Rights Reserved.

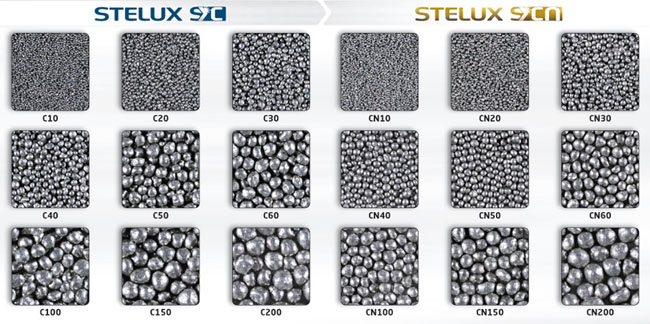

Stainless Steel Shot can be supplied in a relatively low hardness of 30 HRC in the case of the austenitic Chromium-Nickel Stelux CN shot and a higher hardness of 42 HRC in the case of the Chromium Stelux C shot.

Stainless steel shot is used mainly for surface cleaning, preparation and finishing of non-ferrous metals and stainless steel castings or forgings, such as:

Stainless steel shot is used mainly for surface cleaning, preparation and finishing of non-ferrous metals and stainless steel castings or forgings, such as:

- Desanding/deburring of Aluminium castings

- Preparation of Aluminium parts before coating

- Satin finishing before anodisation of Aluminium parts

- Surface preparation of stainless steel products as a substitute to acid pickling

- Polishing of cast/hot swaged parts in Brass, Copper, Bronze or Stainless Steel

Copyright © John Smith, All Rights Reserved.

Cut Wire

Copyright © John Smith, All Rights Reserved.

Cut Wire is produced by cutting wire into a length equal to the wire diameter. This media can be supplied in various different materials, such as Stainless Steel, Carbon Steel, Aluminium, Copper or Zinc. Due to the wide range of wire raw materials available this kind of abrasive can be used for various applications, ranging from paint removal up to high end shot peening processes. This media can also be supplied in conditioned form complying with the latest Aerospace specifications, such as AMS 2431.

Copyright © John Smith, All Rights Reserved.

Aluminium Oxide

Copyright © John Smith, All Rights Reserved.

Aluminium Oxide is an angular and durable blasting abrasive that can be recycled many times. Widely accepted in applications in which high surface roughness requirements exist it is an extremely attractive option due its low cost, longevity and hardness. Harder than most other commonly used blasting materials, aluminium oxide grit penetrates and cuts even the hardest materials and sintered carbide. Approximately 50% lighter than metallic media, aluminium oxide abrasive has twice as many particles per kg. The fast-cutting action minimizes damage to thinner materials by eliminating surface stresses caused by heavier and slower cutting media.

Copyright © John Smith, All Rights Reserved.

Glass Beads

Glass Beads are manufactured from lead-free, soda lime-type glass, containing no free silica that is made into preformed spherical shapes. This media produces a very smooth and bright surface finish due to the gentle cleaning effect. Glass beads blasting produces a clean and bright satin finish without dimensional change of the parts due to the low impact force. They can be recycled in the system approximately 30 times before they break apart.

Available in a wide range of sizes, glass beads are primarily used in blasting cabinets for polishing, light burr removal, general surface finishing and for the removal of foreign matter. Suitable for the blasting of very delicate and thin walled parts that require a gentle surface treatment.

Available in a wide range of sizes, glass beads are primarily used in blasting cabinets for polishing, light burr removal, general surface finishing and for the removal of foreign matter. Suitable for the blasting of very delicate and thin walled parts that require a gentle surface treatment.

Copyright © John Smith, All Rights Reserved.

Ceramic Beads

Copyright © John Smith, All Rights Reserved.

Ceramic Beads are a result of the fusion process of oxides at very high temperatures. Ceramic beads do not contaminate treated parts by embedment of particles and their exceptional properties of toughness, impact resistance and hardness allow them to maintain their initial shape for a prolonged period of time in comparison to glass beads. Their main blasting applications are for the cleaning, deburring, cosmetic surface finishing and peening of parts.

Copyright © John Smith, All Rights Reserved.

Plastic Media

Copyright © John Smith, All Rights Reserved.

Plastic Media is a non-aggressive granulated plastic abrasive used in applications where the underlying substrate cannot be damaged. Plastic media is produced from rejected and recycled mouldings, which are crushed, ground and graded in carefully controlled conditions. It is ideal for the cleaning or stripping of paint, dirt and grease. Other uses include deburring and deflashing composites, Aluminium, Fiberglass and delicate parts, without harming the substrate.

Copyright © John Smith, All Rights Reserved.

Copyright © John Smith, All Rights Reserved.