THL - Tochu Hanger Loop

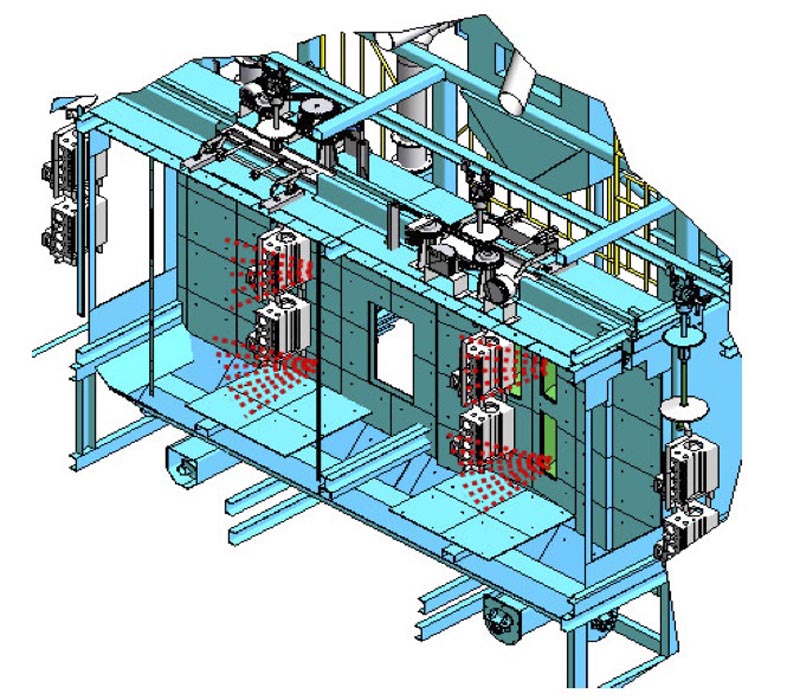

Wheelblasting

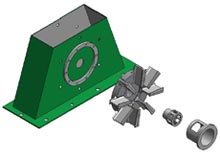

Suitable for the efficient blasting of large workpiece areas and when a high production output is required.

The exclusively metallic abrasive media is thrown by the centrifugal force of the rotating blast wheel in a controlled manner onto the workpieces to achieve the desired cleaning results.

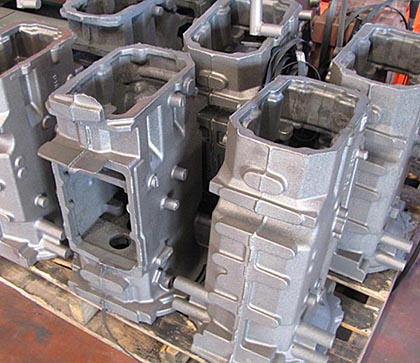

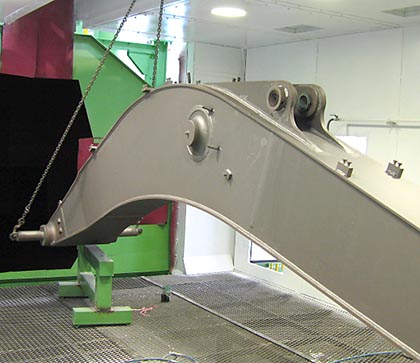

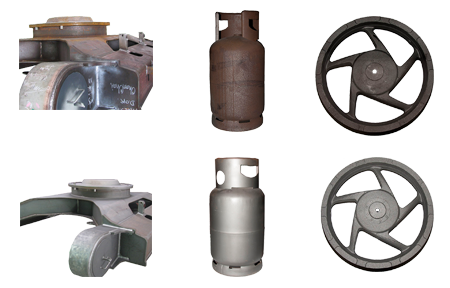

Typical Workpieces

Abrasives

Steel Shot

Steel Grit

Cut Wire

Stainless Steel Shot

(Note: Other metallic abrasives can also be used)

The Tochu Hanger Loop Shot Blasting Machine Type THL is a very popular choice for customers that require cleaning and/or removal of sand from large, heavy cast iron and steel castings. Our flexible hanger loop configuration enables the customer to minimize the space requirements for the equipment, making this machine type the preferred choice within the foundry and forge industry.

- High production capacity

- Fully automated transport of parts during the process cycle

- Blasting of complex part shapes is possible due to blast wheel locations

- Easy machine operation and maintenance